| Talcan Pawder® Series |

Product name | Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | MgO | Al2O3 | Fe2O3 | CaO | CIE L* | Bulk Specific Volume (mL/g) |

Ig.Loss 1000℃/2Hr (%) |

Average Particle Size (μm) |

Apparent Specific Gravity (g/mL) |

||

| Dry L* | Wet L* | ||||||||||

| Talcan Pawder®PK-C | 62.00 | 30.80 | 0.95 | 0.87 | 0.67 | 94.5 | 76.5 | 1.27 | 5.70 | 12.10 | - |

| Talcan Pawder®PK-S | 60.40 | 30.60 | 0.75 | 0.63 | 0.62 | 93.2 | 64.5 | 1.28 | 6.83 | 11.70 | - |

| Talcan Pawder®PK-P | 59.60 | 31.20 | 0.55 | 0.41 | 0.65 | 95.0 | 77.0 | 1.50 | 6.51 | 10.40 | - |

| Talcan Hayashi® | 61.60 | 30.7 | 0.65 | 0.36 | 0.35 | ||||||

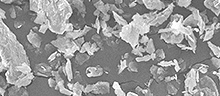

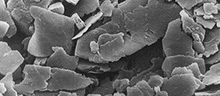

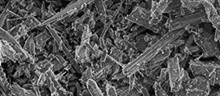

Talc

Only the softest rock-formed mineral talc with high degree of cleavage. This talc is easily exfoliated with a rich smooth texture.

It is also chemically stable which mixes easily with both organic and inorganic materials.

This talc is used in a wide range of useful everyday products. The main applications are resin, paints, rubber, ceramics and pharmaceuticals.

| Micron White® Series |

Product name | Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | MgO | Al2O3 | Fe2O3 | CaO | CIE L* | Bulk Specific Volume (mL/g) |

Ig.Loss 1000℃/2Hr (%) |

Average Particle Size (μm) |

Apparent Specific Gravity (g/mL) |

||

| Dry L* | Wet L* | ||||||||||

| MW HS-T | 58.8 | 33.2 | 0.29 | 0.21 | 0.66 | 95.0 | 77.0 | 2.45 | 6.80 | 4.75 | - |

| Micron White®#5000S | 58.8 | 33.2 | 0.29 | 0.21 | 0.66 | 95.0 | 77.0 | 2.45 | 6.80 | 4.75 | - |

| Micron White®#5000A | 58.8 | 33.2 | 0.29 | 0.21 | 0.66 | 94.5 | 75.0 | 1.95 | 6.80 | 7.10 | - |

| Micron White®#5000R | 58.0 | 33.0 | 0.89 | 0.46 | 0.53 | 93.0 | 62.5 | 2.30 | 7.01 | 4.60 | - |

| Upn HS-T0.5(Compression Products) | 58.8 | 33.2 | 0.29 | 0.21 | 0.66 | 94.5 | 76.0 | 1.11 | 6.80 | 4.75 | 0.50 |

| Upn HS-T0.8(Compression Products) | 58.8 | 33.2 | 0.29 | 0.21 | 0.66 | 94.5 | 76.0 | 0.82 | 6.80 | 4.80 | 0.80 |

| MW YK-T | 59.0 | 32.9 | 0.32 | 0.30 | 0.98 | 95.0 | 77.0 | 2.50 | 7.50 | 4.75 | - |

| MW UPN TT(Compression Products) | 59.0 | 32.9 | 0.32 | 0.30 | 0.98 | 94.5 | 77.0 | 1.00 | 7.50 | 4.75 | 0.50 |

| MW TB 08(Compression Products) | 58.7 | 33.1 | 0.27 | 0.24 | 0.96 | 93.0 | 71.0 | 0.80 | 7.40 | 5.40 | 0.80 |

| GH Series | Product name | Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | MgO | Al2O3 | Fe2O3 | CaO | CIE L* | Bulk Specific Volume (mL/g) |

Ig.Loss 1000℃/2Hr (%) |

Average Particle Size (μm) |

Apparent Specific Gravity (g/mL) |

||

| Dry L* | Wet L* | ||||||||||

| GH7 | 61.0 | 33.2 | 0.22 | 0.26 | 0.35 | 95.0 | 77.0 | 2.50 | 5.25 | 5.80 | - |

| GHL7 | 61.0 | 33.0 | 0.17 | 0.47 | 0.28 | 94.0 | 71.0 | 2.50 | 5.30 | 5.80 | - |

| GHL10 | 61.0 | 33.0 | 0.17 | 0.47 | 0.28 | 94.0 | 71.0 | 2.00 | 5.30 | 8.00 | - |

| GH7(05) (Compression Products) | 61.0 | 33.2 | 0.22 | 0.26 | 0.35 | 94.5 | 77.0 | 1.05 | 5.25 | 5.80 | 0.50 |

| GHL7(05) (Compression Products) | 61.0 | 33.0 | 0.17 | 0.47 | 0.28 | 93.5 | 71.0 | 1.10 | 5.30 | 5.80 | 0.50 |

* Products from Golcha Group from India

| KHP Series | Product name | Chemical Composition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | MgO | Al2O3 | Fe2O3 | CaO | CIE L* | Bulk Specific Volume (mL/g) |

Ig.Loss 1000℃/2Hr (%) |

Average Particle Size (μm) |

Apparent Specific Gravity (g/mL) |

||

| Dry L* | Wet L* | ||||||||||

| KHP-25 | 58.6 | 33.7 | 0.28 | 0.23 | 0.34 | 94.5 | 76.5 | 2.20 | 6.87 | 4.75 | - |

| KHP-20 | 58.6 | 33.7 | 0.28 | 0.23 | 0.34 | 94.5 | 75.0 | 1.90 | 6.87 | 5.95 | - |

| KHP-125 | 58.6 | 33.7 | 0.28 | 0.23 | 0.34 | 94.5 | 74.5 | 2.05 | 6.87 | 7.50 | - |

| KHP-400 | 58.6 | 33.7 | 0.28 | 0.23 | 0.34 | 95.0 | 76.0 | 1.27 | 6.87 | 14.20 | - |

| KHP-25B | 57.6 | 34.5 | 0.31 | 0.15 | 0.10 | 94.0 | 70.0 | 2.20 | 7.39 | 4.75 | - |

| KHP-20B | 57.6 | 34.5 | 0.31 | 0.15 | 0.10 | 94.0 | 70.0 | 1.90 | 7.39 | 5.90 | - |

| KHP-125B | 57.6 | 34.5 | 0.31 | 0.15 | 0.10 | 94.0 | 70.0 | 1.95 | 7.39 | 8.00 | - |

| KHP-400B | 57.6 | 34.5 | 0.31 | 0.15 | 0.10 | 93.0 | 65.5 | 1.00 | 7.39 | 19.50 | - |

| KHP-255(Compression Products) | 58.6 | 33.7 | 0.28 | 0.23 | 0.34 | 94.0 | 76.0 | 1.25 | 6.87 | 4.85 | 0.50 |

| KHP-258(Compression Products) | 58.6 | 33.7 | 0.28 | 0.23 | 0.34 | 94.0 | 76.0 | 0.90 | 6.87 | 5.00 | 0.75 |

* Representative Value

Contact Us for more information about Talc

In addition to the products above we accept special requests and proposals to cater to specific needs and demands.

| Plastic Materials Division | Osaka | TEL: +81-6-6486-9383 |

|---|---|---|

| Tokyo | TEL: +81-3-3257-9330 |

Pagetop

Pagetop